SpaceFAB for Gamma Ray Environment

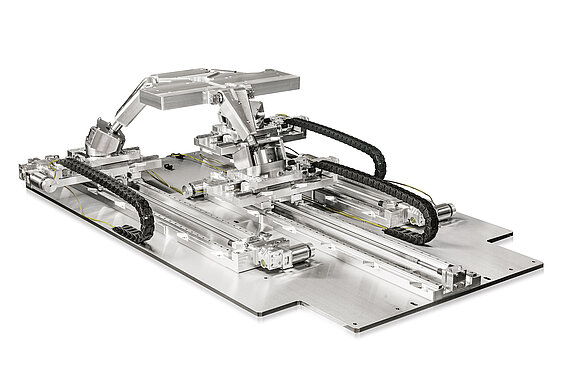

Gamma radiation destroys almost every electronic device. Ionizing radiation not only limits the lifetime of microelectronics, it also disaggregates organic materials which are typically used for isolation and lubrication. For alignment systems for optical components in such a hostile environment PI designed, built and qualified a parallel kinematic machine with six degrees of freedom (DOF) within 30 weeks only. Besides the gamma ray hardness which required appropriate design efforts, the payload of 250 kg and tight space constrains increased the technical complexity of the system.

In addition to three rotational DOF and three linear DOF with a range of ±2°/±2 mm, the application required a “seventh DOF” with a travel range of 550 mm. To meet this requirement, we took advantage of the modularity of the SpaceFAB concept: With little efforts it was possible to increase the travel range in the desired direction by implementing three long travel range stages.

With large travel ranges, a load capacity of 100 kg, and the extraordinary reliability PI’s LS 180 linear stages are ideal components for this customized parallel kinematic machine. Also for the use in this extreme environmental condition which prohibits the use of any encoders, LS 180 linear axes are the right choice. Due to their inherent high precision the LS 180 stages achieve the demanded accuracy in open loop mode easily. This is realized by the use of high quality stepper motors and low backlash worm gears in combination with precision guides and ball screw drives. Instead of optical limit switches, which would be destroyed by radiation after a short time, mechanical switches are implemented. Not only the linear stages, but also all other components have been designed very carefully. The leg design, which includes the upper and lower joints, combines high stiffness and smooth motion with functionality and reliability always in focus. Self-evident, that the customized top plate provides the perfect mechanical interface for the customer’s payload.

Due to the ionizing radiation any repair procedure can only take place after several months of decay time. Therefore any significant malfunction of the positioning system can lead to a long downtime at the customer’s site. In case a component has to be replaced, the design allows excellent access to motors, gearboxes and switches, but we don’t think that this is ever necessary.

Specifications

| Parameter | Specification |

|---|---|

| Range X | ±2 mm |

| Range Y | ±2 mm |

| Range Z | ±2 mm |

| Range rot X | ±2° |

| Range rot Y | ±2° |

| Range rot Z | ±2° |

| 7th DOF in X | 550 mm |

| Linear bi-directional Repeatability | 6 µm |

| Angular bi-directional Repeatability | 0.00038° |

| Maximum Load | 250 kg |

| MIM rot | 0.001° |

| MIM linear | 2.5 µm |