Access award winning solutions to achieve high-performance:

Understanding your individual needs to build our futures together

- Market-proven solutions for laser processing

- Competent advice - right from the start

- Flexible configuration and application-specific adaptation

- Different integration levels and high integration capability

- Comprehensive solutions that combine ease of use and smooth operation while increasing productivity

- High economic profitability

- Servicing and support - Always near you - worldwide

For more information about PI’s positioning and motion control solutions in industrial applications, speak with your local PI applications engineer.

Are you looking for help with your high-performance laser application?

You have come to the right place!

PI has the UK's expert application engineers who are ready to help you solve your technical problems.

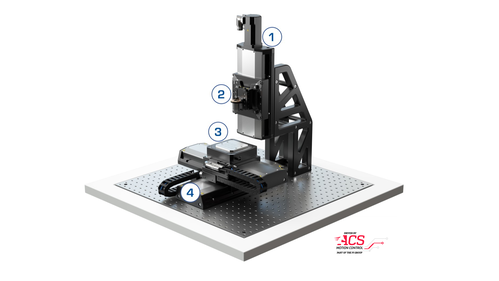

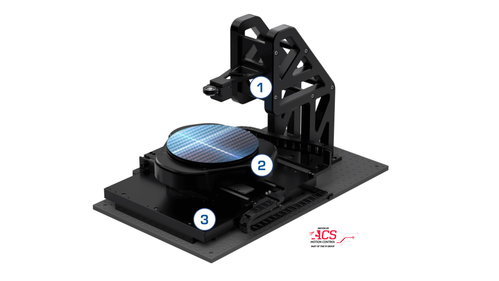

In order to develop the appropriate positioning solution that can also be optimally integrated into the application, PI works closely with its customers right from the start. Due to the variety of technologies and experience in precision positioning and automation, PI can react flexibly to the requirements of laser technology and offer motion solutions that meet customer needs:

- From single and multi-axis systems without beam deflection to highly customised solutions where the motion of galvanometer scanners and the positioning systems have to be synchronised and are able to run simultaneously.

ACS Motion Control, as part of the PI Group, allows the supply of highly sophisticated automation and motion controllers with a wide range of drive options and dedicated modules for the control of laser applications.

You can find out more about our broad portfolio for Performance Automation here.

ECMsm

2 or 4 Axis Motion Controller with Integrated Servo Drives

- Controller and Drive Axes: 2 or 4

- Host PC/PLC/PAC Communication: TCP/IP, Ethernet/IP, Modbus, RS-232

- Controller Cycle Rate: 1kHz

- Drive Supply Input: 12-48Vdc

- Bus Voltage: Equal to drive supply input

- Max Current Output Per Axis: 5/10A

- Encoder Channels: 4 (AqB, Absolute, or SinCos)

- Mounting Type: Panel

- Functional Safety Options: STO & SS1

IDMma

2 or 4 Axis DS402 EtherCAT® Intelligent Drive Module up to 10/20A at 150VDC

- Communication Protocol: EtherCAT DS402 (CiA402) CoE

- Max EtherCAT Cycle Rate: 4kHz

- Real-Time ACSPL+ Program Threads: 4

- Drive Axes: 2 or 4

- Drive Supply Input: 24-150Vdc

- Bus Voltage: Equal to drive supply input

- Max Current Output Per Axis: 15/30A up to 100Vdc, 10/20A up to 150Vdc

- Mounting Type: Panel

- Functional Safety Options: STO & SS1

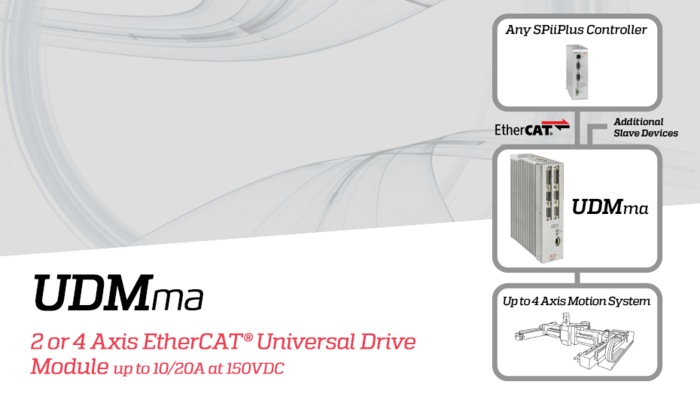

UDMma

2 or 4 Axis EtherCAT® Universal Drive Module up to 10/20A at 150VDC

- Drive Axes: 2, 4

- Drive Supply Input: 24-150 Vdc

- Bus Voltage: Equal to Vin

- Max Current Output Per Axis: 15/30A up to 100Vdc, 10/20A up to 150Vdc

- Encoder Channels: up to 4

- Mounting: Panel

- Functional Safety Options: STO, SS1

- Proprietary ACS Feature Options: ServoBoost, Non-Linear Control

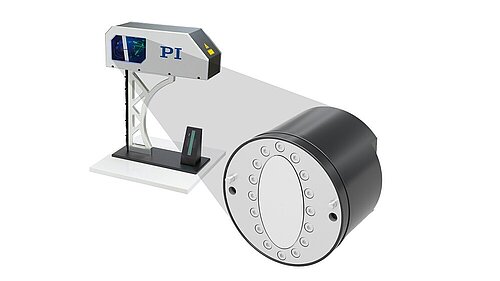

LCM EtherCAT® Laser Control Module

Enables direct control of a laser source with full synchronization to motion

- The LCM is designed to meet the needs of laser processing system OEMs with demanding throughput and accuracy requirements.

- Working under any ACS SPiiPlus Platform EtherCAT master controller, the LCM tightly synchronizes control of a fixed beam laser with motion.

- Sub-microsecond latency enables high-accuracy laser micromachining, while high pulse frequencies enable high levels of throughput.

SPiiPlusSPC Smart Processing Commander

Machine Control Interface for High-Precision Laser Processing Applications

- Flexible CAD-to-motion import and design

- 2D and 3D processing modes

- Laser Control Module support for accurate fixed beam laser triggering, dynamic power control

- Dynamic Position Monitoring

- Flexible processing architectures

- Rich galvo scanner and vision system calibration features

- Pre-developed support for leading galvo, laser, and camera suppliers

- Customization Options via C# plugins

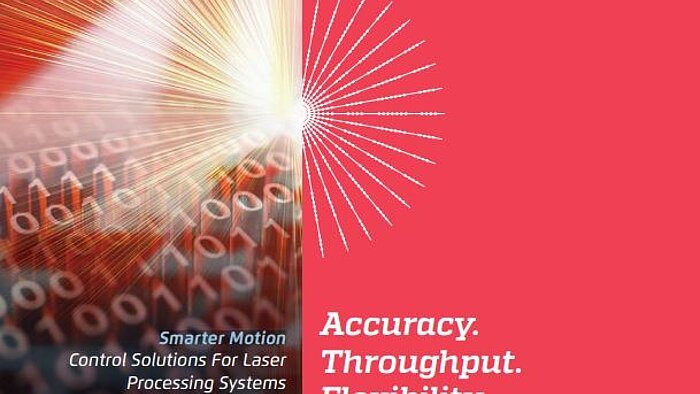

Laser Processing Control Solutions Brochure

Smarter Motion Control Solution for Faster Laser Processing Systems

ACS Promise

We are always ready to rise to the challenge to deliver smart, best-performing motion control solutions for the most demanding applications, developed and supported in partnership with you and in-line with your needs.

ACS Motion Control Brochure

High-Performance OEM Motion Control Solutions

ACS and its partners tailor motion control solutions with standard products to meet your unique requirements.

- Motion controllers

- Motion controllers with integrated drives

- Motor drives

- Drive interfaces

- Laser interfaces

- Auxiliary products

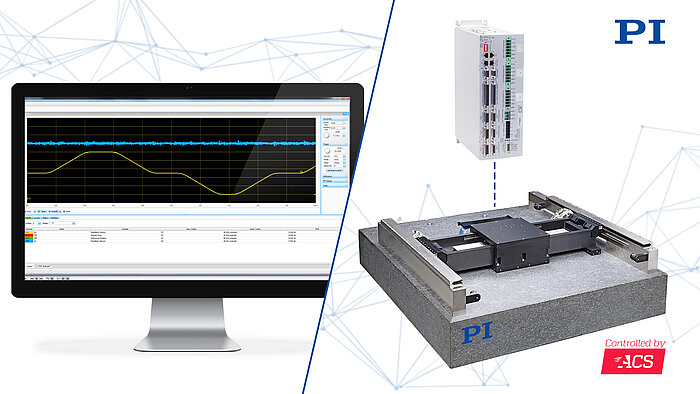

Smarter Gantry Control

Improve Throughput and Accuracy with Advanced MIMO Control Algorithm

- MIMO decoupled control of linear position and yaw displacement loops

- Independent tuning and optimization of linear and yaw control loops

- Dynamic cross-axis center of mass compensation

- Error mapping compensation (orthogonality, straightness...)

- Dual-loop gantry control

System Optimisation and Support

UK based support tailored to your needs

- System implementation, mechanics, controller and peripheral devices

- System optimisation including tuning

- Fault diagnosis including root cause analysis and corrective action

- Training

Downloads

Automation Platforms for Laser Material Processing

Precision – Throughput – Synchronized Motion