Piezo Ceramic Components & Transducers for OEMs

Piezo Custom Assemblies, Miniature Piezo Transducers, Working with OEM's, Instrumentation Manufacturers

Developing and manufacturing piezo ceramic materials and components are complex processes. PI Ceramic - PI’s piezo material design and manufacturing facility - boasts several decades of experience as well as the right tools for rapid prototyping of custom engineered piezo components and assemblies. From the formulation of advanced piezo materials to the processing steps such as cutting, milling, grinding, and the precision assembly, every stage is controlled by our engineers and product specialists.

Close Cooperation with Our Customers from the Prototype to Large Production Runs

PI Ceramic's process control allows the transition from test samples to large production runs in a reliable and cost-efficient way while maintaining the high quality our products are known for. PI Ceramic has a track record of working closely with OEM instrumentation manufacturers. Our engineers have the knowledge and experience to analyze the requirements and understand the application. They work with our customer's engineers to find the best standard product or design a custom part or assembly.

Based on expertise gained in more than 40 years of continuous research and manufacturing of piezoelectric material and components, PI Ceramic can provide world-class high-performance piezoelectric actuator and transducer components and subassemblies. Read about PI Ceramic.

Individual advice often is key to solve a complex problem. PI sales engineers are ready to come on site with all the time necessary for a solid understanding of the topic. Or they will gladly meet at the PI office in Cranfield.

Component Types and Applications

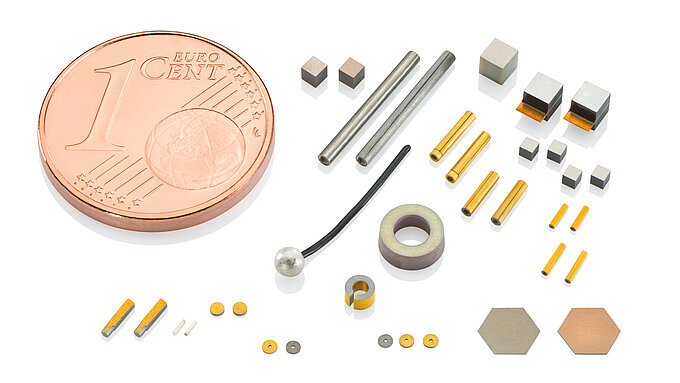

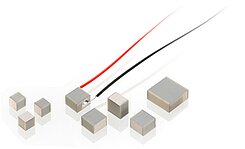

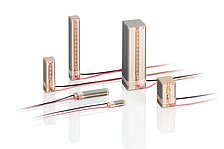

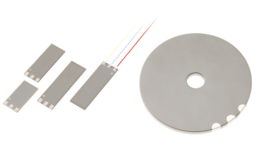

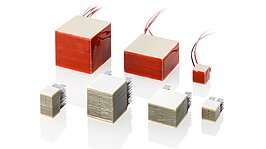

PI Ceramic manufactures piezo components, including tubes, rings, plates, discs, and spheres that can be used in applications such as medical ultrasound technologies, level and flow control and measurement, ultrasonic welding and cleaning, bubble detectors, and proximity sensors, echolocation (sonar) etc.

Dimensions and Physical Limitations

The product groups above are available with custom shapes and dimensions, with limits determined by the production tools and minimum dimensions based on physical and technological limits. The minimum thickness or wall thickness of a piezo component is limited by the mechanical strength of the ceramic material required during the machining process. The maximum thickness in the polarization direction is 30mm.

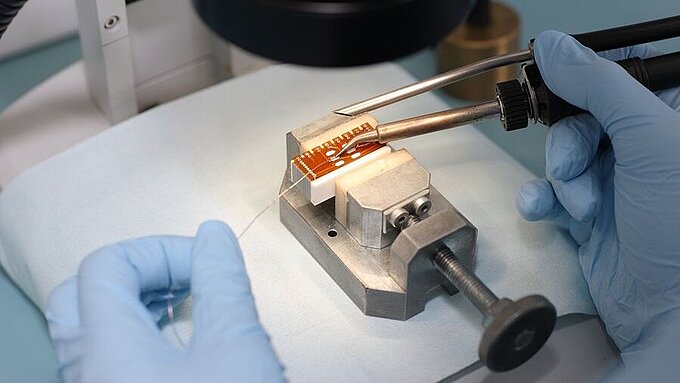

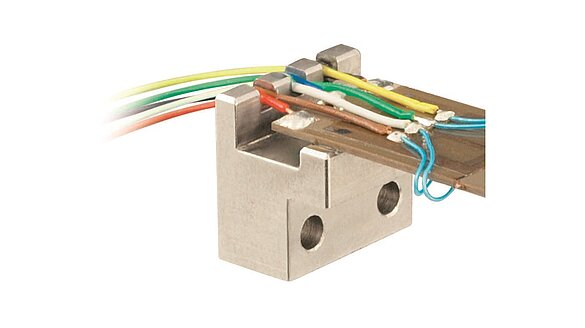

Value Added Assemblies / Integration / Customisation

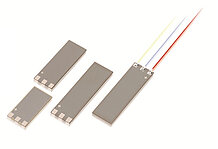

PI Ceramic is experienced in providing value added products by integrating a piezo ceramic component into a customer’s sub-assembly or product. This includes electrical contacting of the piezo elements according to customer requirements, mounting of customer provided components, and gluing or casting of the piezo ceramics.

PI Ceramic has access to state-of-the-art machines and technologies and can ramp up quickly components to provide piezo components in large quantities at short notice.

Find out more about the assembling technology at PI Ceramic.

Individual advice often is key to solve a complex problem. PI sales engineers are ready to come on site with all the time necessary for a solid understanding of the topic. Or they will gladly meet at the PI office in Cranfield.

Brochures

Lead-Free Piezoceramic Materials

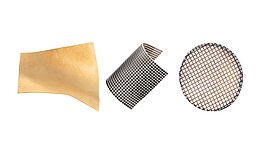

Piezoceramic Composites

Piezo Components for Liquid Handling

Microfluidics for in Vitro Diagnostics

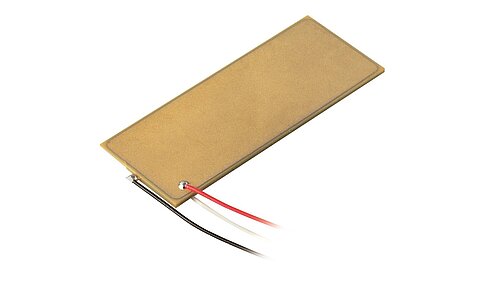

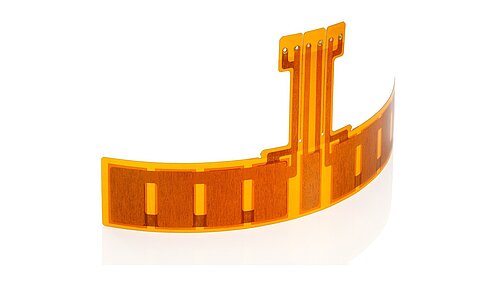

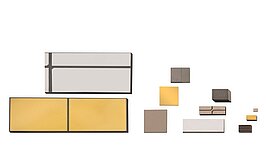

DuraAct Piezoelectric Patch Transducer

Flexible, Efficient, Durable

PI Piezo Drive Solutions

For Medical Engineering

Handling of PI Piezo Actuators

Instructions for careful handling

PI Ceramic Product Overview

The Specialists for Piezo Technology

Dynamic Behaviour

Oscillation modes of piezoceramic elements