Advances in Laser Micromachining and Microprocessing

New Motion Control Approaches Deliver Improved Accuracy and Faster Time to Market

Introduction

Experienced Laser Microprocessing and Micromachining system integrators have no trouble providing proof of concept demonstrations for new applications. Turning the concept into a robust solution is a different story altogether – at least it used to be. Here is why: Delivering laser pulses to the workpiece with a high degree of accuracy and repeatability, and developing and maintaining the human machine interface (HMI) software, are among the most complex and resource intensive efforts involving a variety of technologies and disciplines such as CAD/CAM post processing, motion profile generation, user interface and host programming, motion programming, laser control and real time IO control.

Many of the aforementioned challenges are now solved thanks to newly available motion / CNC controller technologies that reduce complexity and allow the designers to bring a machine to market faster, while improving the process accuracy at the same time.

Reducing Time to Market with an HMI Development Platform

The Laser Micromachining / Microprocessing HMI software is a critical component or subsystem of the machine and typically falls into one of two classifications:

- A ‘CNC Style’ HMI which imports and executes machine code programs (typically G&M Code) created by a CAM software post processor

- An ‘Integrated Graphical’ HMI which allows import and manipulation of CAD files and provides integrated CAM / post processing functionality

Some Motion and CNC controller companies now offer customizable HMI development platforms for both types of HMIs, allowing the system integrator or OEM to take a new, less resource intensive approach to developing and maintaining their HMI software: building the HMI application with the customizable platform.

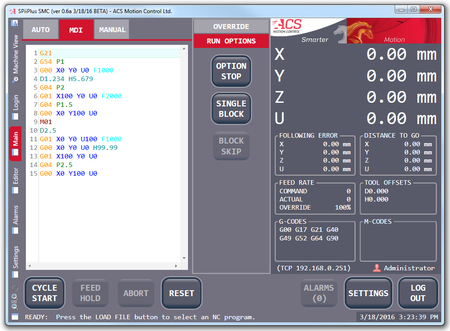

The CNC Style HMI

Many Laser Micromachining / Microprocessing systems are used in a machining or manufacturing environment alongside other ‘traditional’ CNC machines – lathes, mills, routers, etc. Having commonality between the Laser System HMI and the HMIs of the other machines is beneficial to the manufacturer as it leverages on existing knowledge and experience of the manufacturer’s machinists and technicians.

A customizable CNC HMI development platform can be expected to provide many standard HMI features out of the box, such as:

- The ability to load, edit, and execute NC files with Standard RS-274 and user defined G & M Codes

- Flexible CNC program flow control options such as stop, hold, abort, single block run, block skip, and feed rate hold (fig. 1)

- Real time monitoring of program execution, axis positions, feed rates, G/M code modality, alarms and faults

- Multi-tiered user access login screens for operators, technicians, developers, administrators, etc.

Many challenges associated with integration of the HMI host application and the motion / CNC controller are also solved:

- Optimizing NC program download, compilation, and execution time

- Managing G/M Code modality in order to support ‘mid-program start’

- Displaying, handling, and logging machine fault and error conditions

The competitive advantages of a Laser Microprocessing and Micromachining system are often related to application specific functionality. As the name implies, a customizable CNC HMI development platform provides value to the machine developer by allowing application specific HMI customization with relatively little effort. Simple examples of such customizations may be custom tabs, buttons, or screens.

More sophisticated customizations may involve process visualization or integration of other devices in the machine such as cameras and laser displacement sensors.

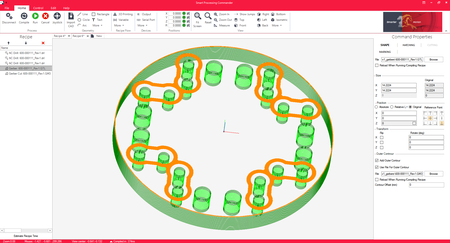

The Integrated Graphical HMI

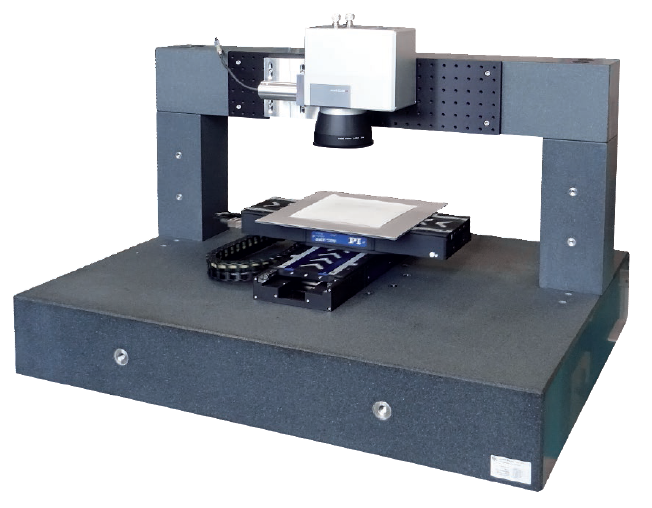

Laser Microprocessing and Micromachining systems used in applications such as flex PCB drilling and cutting, glass and polymer display processing, semiconductor processing, precision optics manufacturing, high precision additive manufacturing, and more, are often used in high-tech research and production facilities. In such as the system operator is not a CNC machinist. The Integrated Graphical HMI can directly take in a CAD file from which a laser path is defined and the corresponding machine code is then automatically generated and executed on the motion controller (figure 2). In such cases, a separate CAM or post-processing software is not required.

A customizable Integrated Graphical HMI development platform, with built in functions for specific processes such as laser marking, drilling, etching, cutting, additive manufacturing, etc. provides significant added value to the machine builder / integrator and end user by solving a number of development challenges out of the box:

- A wide range of CAD files are natively supported (DXF, DWG, Gerber, NC Drill, STL, etc.) and can easily be manipulated to easily create motion recipes (scaling, rotation, tiling, etc.)

- Parameters for all motion axes can be configured and monitored from a single window / location

- Real time monitoring and data collection of motion feedback, laser status

- Commonly used devices such as cameras and Galvo scanners are natively supported and configurable within the HMI. New devices can easily be integrated as well (no need to write new libraries from scratch)

- Full simulation capabilities allow the user to see the expected laser beam path and determine expected process duration

Similar to a CNC Style HMI development platform, an Integrated Graphical HMI development platform can be also customized for application specific functionality.

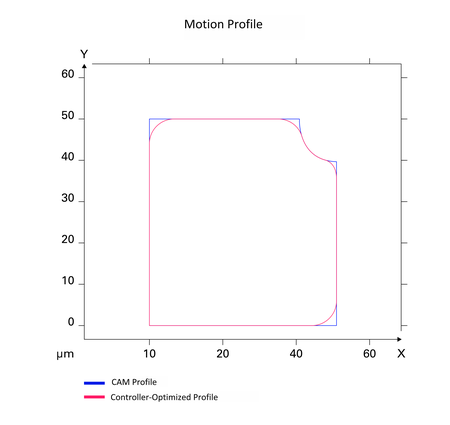

Improving Process Accuracy and Repeatability with Motion Performance Optimization and the Laser Control Module

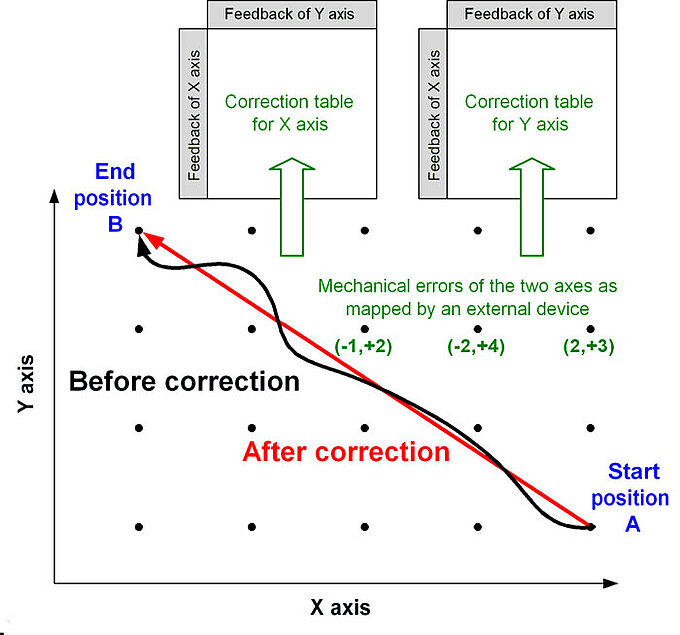

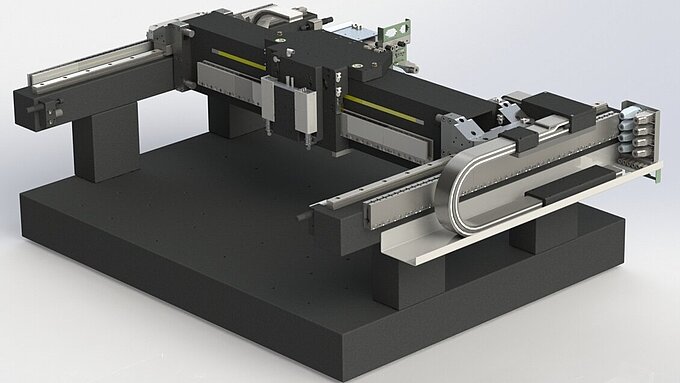

For many laser microprocessing and micromachining applications, the motion performance is critical in determining the achievable accuracy and repeatability of the process. Motion performance is affected both by the profile generation (commanded motion path) and the servo performance (how well the actuators / stages follow the commanded motion path). Today’s sophisticated motion / CNC controllers provide advanced profile generation and servo performance optimization features, such as:

- Minimal energy profile generation

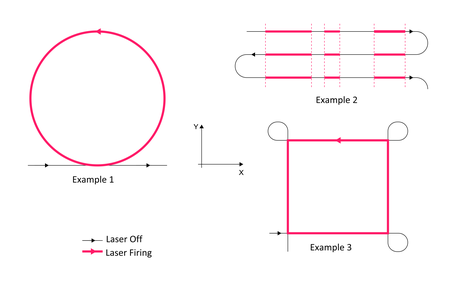

- Motion segment blending and corner smoothing (figure 3)

- Adaptive servo control algorithms

- Autotuning and performance characterization tools

- Advanced PWM drive technologies

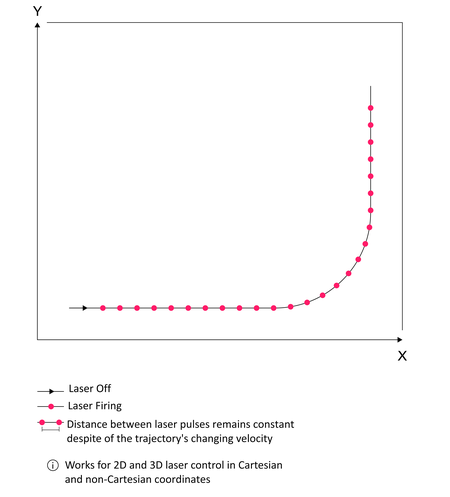

In addition to motion performance, position based output synchronization also has a significant impact on laser microprocessing and micromachining accuracy and repeatability. This task has traditionally been handled within the motion / CNC controller or drive that is physically connected to the machine actuators.

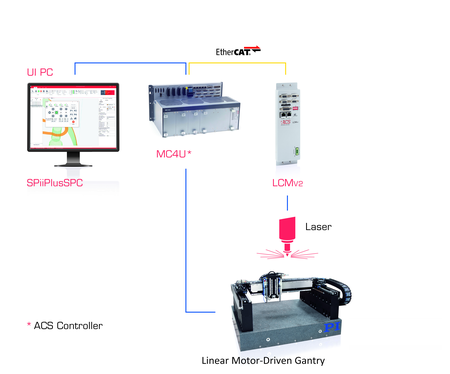

Recently however, dedicated laser control modules have become available, which provide additional flexibility and capabilities with respect to provides position based output synchronization for laser triggering (figure 4) and gating (figure 5). Once added on to a motion control network, the module can be configured (via software) to provide synchronized outputs based on motion of any combination of axes in the network. The laser control module can be configured to operate in various ‘laser control modes’, making it simple to implement a wide variety of applications:

For applications where the laser pulses are not triggered individually by an external control system, a gating mode can be used. In such applications, the gating signal is typically turned on / off precisely at the beginning or end of a motion segment or block, though it can also be done at arbitrary locations along a motion path.

Digital modulation modes for power control are also possible, such as pulse width modulation (PWM) and frequency modulation (PFM). Operating modes can be combined simultaneously for even more advanced applications (Figure 6).

Conclusion

Many of challenges of the past associated with developing a robust and scalable Laser Micromachining /Microprocessing platform, have been addressed by new technologies from motion / CNC controller providers, enabling better machine performance and reduced development effort, leading to big gains when it comes to minimizing time to market.