Improved Contour Machining for Wing Shells for the Wing of Tomorrow Project

Milling, Deburring, Sealing, and Drilling

As a partner in the LuFo VI-1: ADMAS (Advanced Machining and Sealing) research project, PI presented a new custom-designed hexapod at the International Aerospace Exhibition ILA Berlin in June 2024.

As part of a joint project under the leadership of Airbus, PI developed a high-performance 6-DOF hexapod motion and positioning system (model H-900K101) for highly dynamic compensation kinematics in aircraft construction. The project's goal was to enhance the processing and sealing precision of carbon fiber-reinforced composite (CFRP) components in resin transfer molding (RTM) manufacturing processes, while also reducing manufacturing time and process costs.

Carbon fiber composites combine high stiffness with low weight, helping increase energy efficiency in aviation and reduce CO2 emissions.

Dynamic Compensation of Process Forces

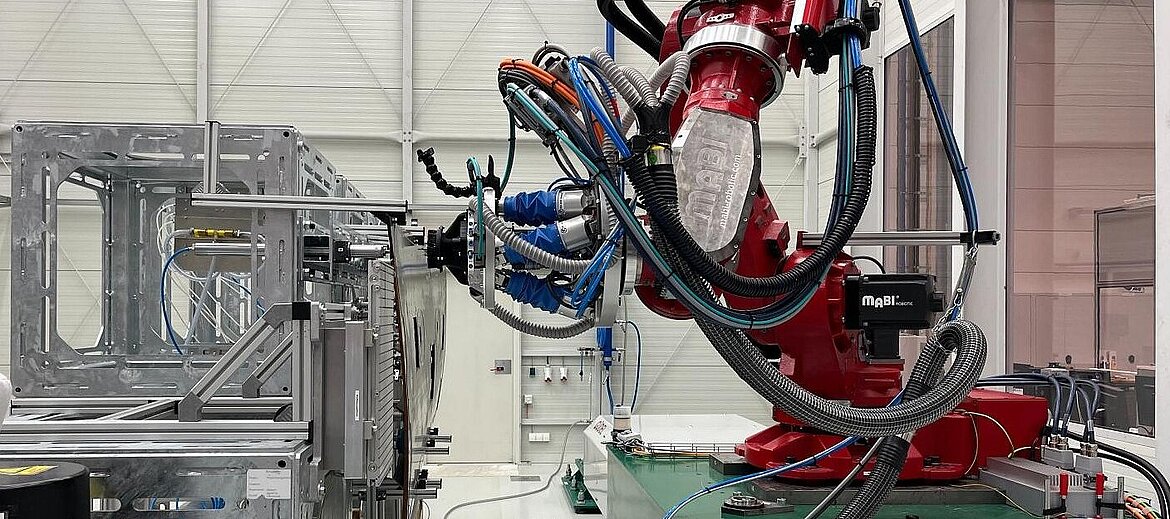

The compensation kinematics focus is on the contour machining of the single-aisle wing shells for the Wing of Tomorrow project made of CFRP by means of milling and deburring as well as their subsequent sealing and drilling. The H-900K101 hexapod of PI, combined with the coarse motion of a traditional articulated robot, is used for highly dynamic, high-precision positioning of the machining and sealing tools.

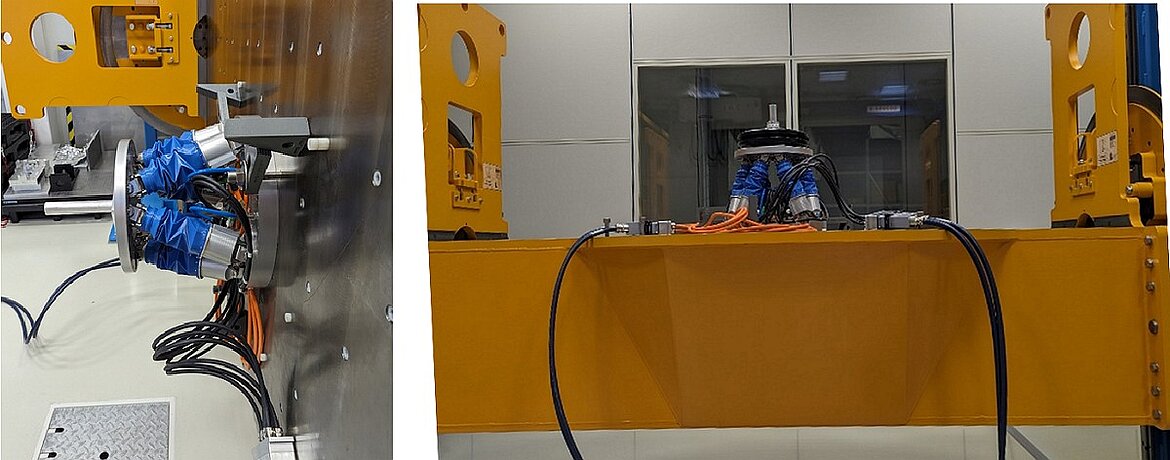

“With the new H-900K101 hexapod, we have implemented a highly dynamic system that can accelerate a payload of up to 40 kg in the XY plane at up to 1.2G," says Dr Christian Sander, Head of Technology Development Parallel Kinematics at PI’s headquarters in Karlsruhe, Germany. “The system is able to dynamically compensate for high-frequency path deviations under the influence of process forces during milling.” Compared to the previous mode, the new design offers improvements such as a lower center of gravity, a lower operating height, and many other optimizations.

Fine Positioning of Tools

The newly developed hexapod system was designed for the specific boundary and environmental conditions of the application and is therefore particularly optimized for the time-critical manufacturing processes with the tight tolerances required by the aerospace industry.

In addition to this high dynamic performance, the hexapod system offers fiber optic data transmission between the hexapod controller and the driver electronics. The system is also characterized by a very short latency time when used with an EtherCAT® interface and components sealed in accordance with protection class IP54. Fiber optic data transmission allows the hexapod controller to be conveniently located in the control cabinet outside of the machining cell without compromising the variety of interfaces, while controlling the driver electronics over a distance of up to 100 m (330 ft). For the EtherCAT® interface, PI has achieved a deep integration of EtherCAT® functionality into its controller and driver architecture. As a result, PI's positioning system contributes minimal dead time to the complex path error compensation loop between the edge-detection sensor system, the articulated robot, and the hexapod. The response time in the EtherCAT® control loop between the hexapod's position request and position response is a fast 1.5 ms.

Condition Monitoring

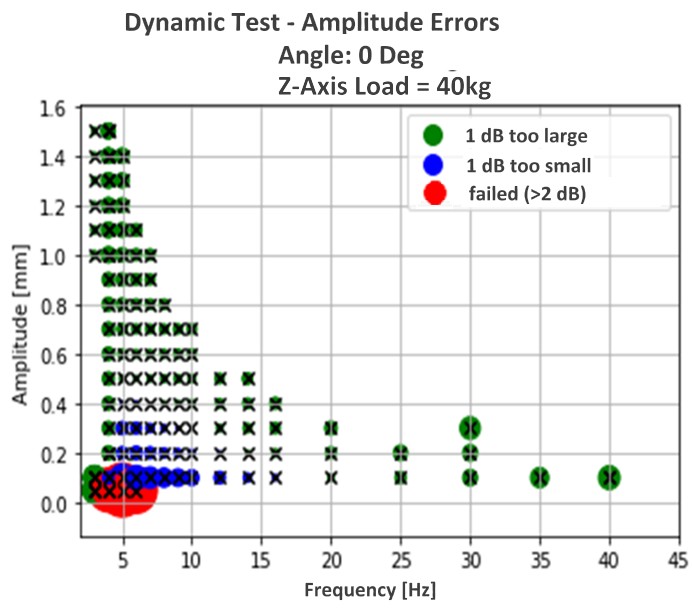

The LuFo VI-1: ADMAS project also investigated the use of acceleration sensors for wear detection on individual hexapod struts in the context of condition monitoring. The frequency spectrum of vibrations within a single strut can be mapped to characteristic eigenfrequencies of drive components, providing an indicator of system changes and the need for service.

Hexapods: Parallel-Kinematic Motion Systems

Hexapods are parallel-kinematic systems that enable motion in six degrees of freedom in a smaller space than traditional serial kinematic motion systems. For industrial applications, absolute position sensors for each hexapod strut provide safety and render referencing unnecessary. All coordinate transformations run on the motion controller and user-friendly software allows the execution of complex motion profiles. PI's precision hexapods are available in standard configurations for loads from 1 kg to 250 kg with repeatability down to ±0.06 μm. Customized precision hexapods can support loads in excess of 2,000 kg.

With travel ranges from a few millimeters to several hundred millimeters, the systems enable precision down to the nanometer range and velocities from 0.1 mm/s to 500 mm/s. PI hexapods are used worldwide in applications including automation, metrology, photonics and optics alignment, automotive, medical technology, astronomy, and research. Depending on requirements, they can be specified for environments such as laboratory, cleanroom, high vacuum, and ultrahigh vacuum.

Under the leadership of Airbus and the IFAM, PI contributed its four decades of experience in hexapod design to this pioneering research. The project, which was publicly funded by the German Federal Ministry for Economic Affairs and Climate Protection and supervised by the DLR Project Management Agency for Aviation Research, was successfully completed at the end of April 2024.

The Fraunhofer Institute for Manufacturing Technology IFAM in Stade, Germany, was tasked with building the overall system demonstrator and addressing the research topics within the project and the individual partners, while applying its valuable application knowledge.