When it comes to precision motion control at the micron or sub-micron or even nanometre level the choice of controller technology for complex applications is very limited. In laser material processing, for example, there is an increasing demand placed upon the system builder to increase both the precision and the throughput of a process. Using the correct mechanics is one key aspect of this however, to optimise performance it is the controller platform which is absolutely critical.

The motion controller needs to be able to communicate efficiently with the mechanics, the laser and any other integrated module. Co-ordination between the motion and other processing activities is critical to ensure optimum productivity and repeatable part precision. An individual part may require a number of different processes such as radial cutting, scribing and vision inspection all on the same machine. The tools and processes to follow for each manufacturing step need to be optimised if maximum production throughput is to be achieved. To support this the controller needs to provide communication reliability and flexibility, offer path control algorithms and provide the end user with the opportunity to optimise process steps both on and off the machine.

Dynamic control of the laser both in terms of its power and application is a critical feature and a must have when the application is pushing a system to its limits. Triggering laser pulses based on time or position and setting laser on or off gates are basic must have features, as is the ability to combine any of these together to offer more complex control capability.

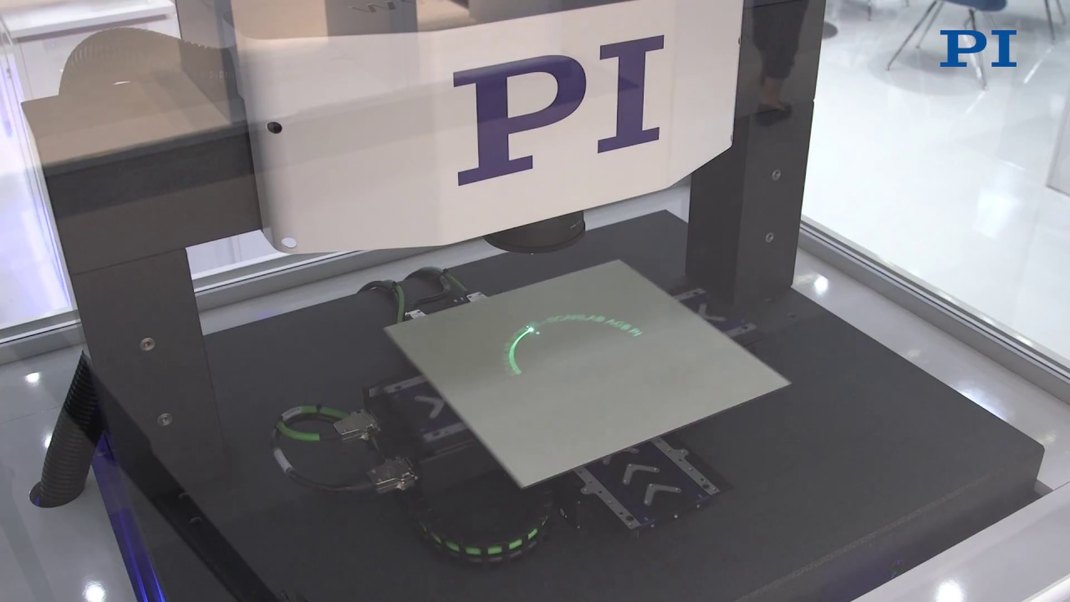

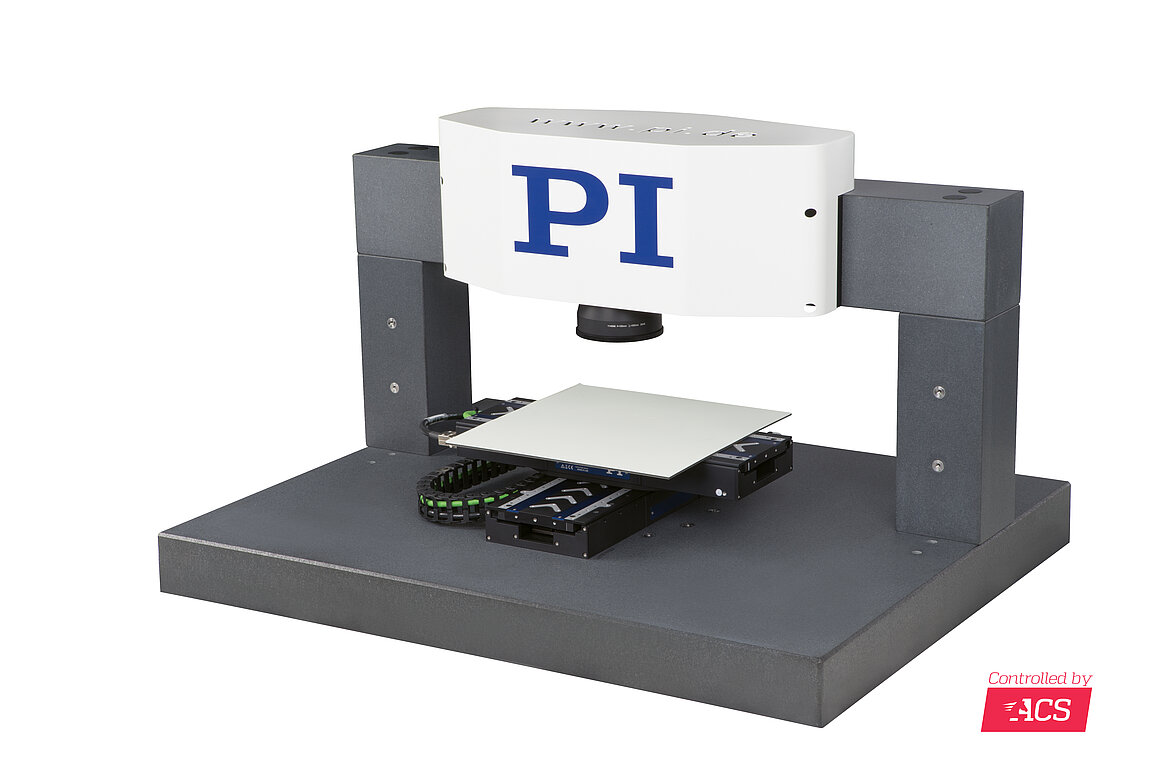

The ACS SPiiPlus Motion Controller platform provides the end user with a modular set of hardware and software tools, including a virtual test environment (simulator). The platform is based on the EtherCAT real time and deterministic open Ethernet communication protocol developed by Beckhoff and widely used in the industrial drives market. ACS focus on precision motion and include features specific to applications in the photonics sector including lasers, vision and optics control. Now part of the PI group ACS controllers and PI industrial mechanics offer a new solution for demanding photonic alignment applications.

At PI we recognise that moving to a new controller platform involves risk and a considerable investment in time for our customers. To support this activity we are able to provide a range of software and hardware tools for technology familiarisation as well as knowledgeable personnel who can provide training and support as and when needed.

To see PI and ACS in action you are welcome to visit our new facility in Cranfield.

ACS website: www.acsmotioncontrol.com.