Hexapod 6-Axis Alignment System Provides Flexibility in Dimensional Measuring Machine in Automotive Applications

The ever higher demand on the performance of headlights in automobiles drives automation and precision requirements of suppliers. A novel compact dimensional measuring machine designed by the DYMACO Group now makes use of 6-axis parallel positioning and alignment system to provide more flexibility for in-line automated dimensional measuring of headlamps in the Automotive Industry.

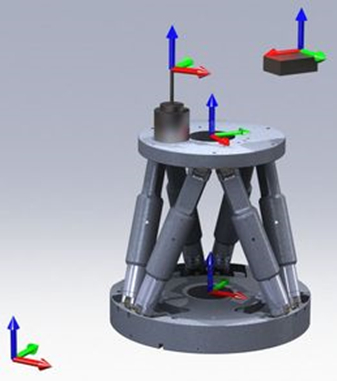

The system uses specific measurement points for initial calibration based on CAD data of the lamp. The lamp is picked from the production line and placed inside the inspection machine onto the hexapod 6-axis positioning system. The sample is adjusted quickly inside the machine to any defined position in 6D space with precision in the micron-range. This is a fully automated metrology process according to the calibration data.

Flexibility for Automated Production Processes

Due to the versatility of the parallel kinematics design with user programmable center of rotation and coordinate system, as well as its compact dimensions, the machine provides outstanding flexibility for a large variety of samples of in-line automation systems. The DM metrology series excel in their high flexibility, reliability, simplicity, compact design, and easy programmability. Their high accuracy combined with high speed make the DM401 Series the ideal choice for automating inspection applications.

Parallel Kinematic Machines (PKM)

In a parallel-kinematic multi-axis system, all actuators drive only one single platform resulting in extremely low moving mass (inertia) high stiffness and excellent dynamics and step/settle performance with high precision. Hexapods provide motion in XYZ and pitch, yaw, roll, and come in different configurations for applications including fiber optic alignment, motion simulation / cancellation, and image stabilization. Load capacities range from 2kg to several tons.