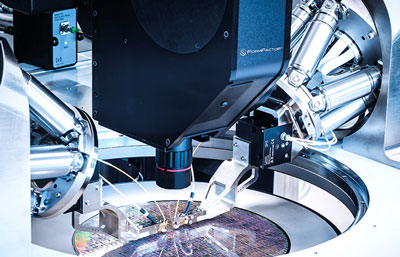

Manufacturing and quality assurance processes in electronics production, mechanical engineering, and the automotive industry increasingly require multi-axis positioning systems. At the same time, the requirements in terms of accuracy are also increasing.

Depending on the model, parallel-kinematic hexapod robots can move and position tools, workpieces, and complex components with weights ranging from a few grams to several hundred kilograms or even several tons in any spatial orientation with high precision – regardless of the assembly orientation.

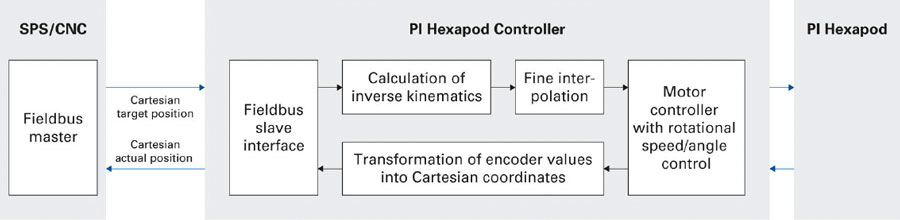

The PI hexapod controller with integrated EtherCAT® interface now makes it very easy for users to integrate hexapods into automation systems without it being necessary to perform challenging kinematic transformations.

The EtherCAT communication is based on the CANopen over EtherCAT (CoE) protocol and therefore offers the same communication mechanisms that are defined in the CANopen standard according to EN 50325-4. The minimum permissible cycle time for the hexapod controller is one millisecond. The Object Dictionary, Process Data Object (PDO) Mapping, and Service Data Objects (SDO) are supported.

PDOs and SDOs have been defined according to drive profile CiA402 in order to allow easy integration of the Cartesian axes of the hexapod within the PLC.

In our free white paper you will learn more about:

- How the integration works

- How Work and Tool coordinate systems can be used and

- How the range of motion of the hexapod is optimally used

Author of the white paper is Dr. Steffen Schreiber. He is Senior Expert on Hexapod Development at PI (Physik Instrumente) and he has been working for many years with fieldbus systems, especially EtherCAT®.

My motivation is to optimally integrate parallel kinematic systems such as hexapods into the process environment and thus to offer our customers the opportunity to benefit from the advantages of hexapods.

Dr. Steffen Schreiber

(Senior Expert on Hexapod Development)