High-Speed Deformable Mirror for Laser Beam Focus Control in Cutting & Welding Applications

Piezo driven laser focus shifter module advances speed and quality in laser machining applications

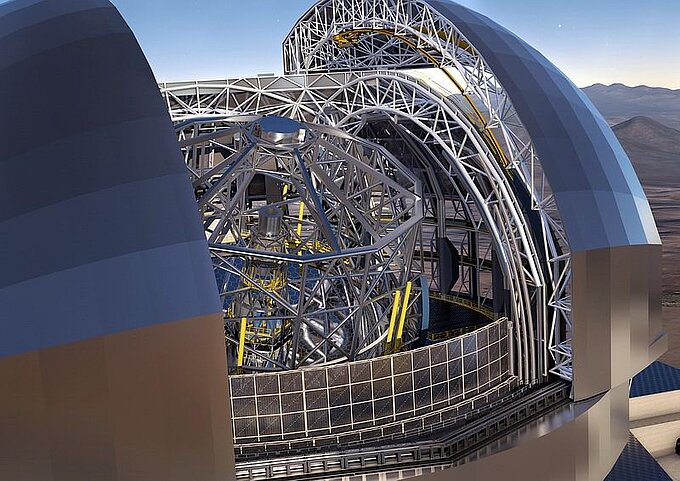

Piezo ceramic actuators combine rapid response with high resolution and high force generation, ideal prerequisites to drive highly-dynamic deformable mirrors. The principle has been used in adaptive optics for applications including astronomy, microscopy, surveillance and defense. Imaging applications, such as the aforementioned ones, typically involve a multitude of actuators per mirror to correct for wave-front aberrations.

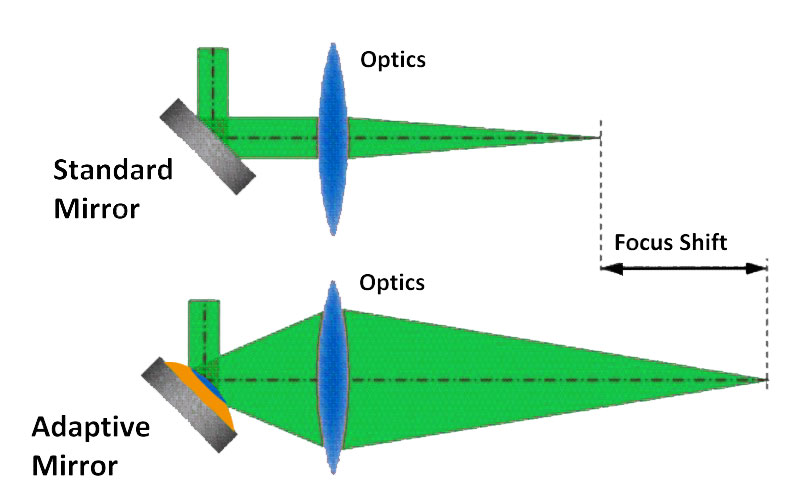

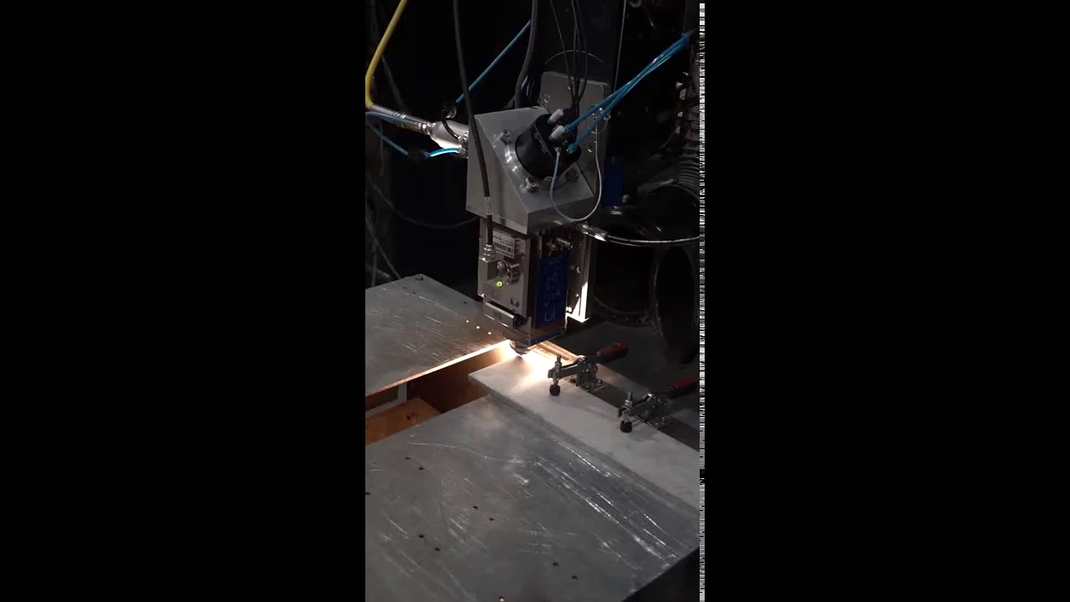

In addition to imaging, machining applications can also benefit from active and adaptive optics. Lasers have long made the transition from the lab to the manufacturing floor. They are tools used in a variety of production processes and guarantee highly repeatable workpiece quality. Improvements are feasible by controlling and geometrically manipulating the laser beam. High-frequency beam oscillation in the XY plane with scanning mirrors has already been used successfully.

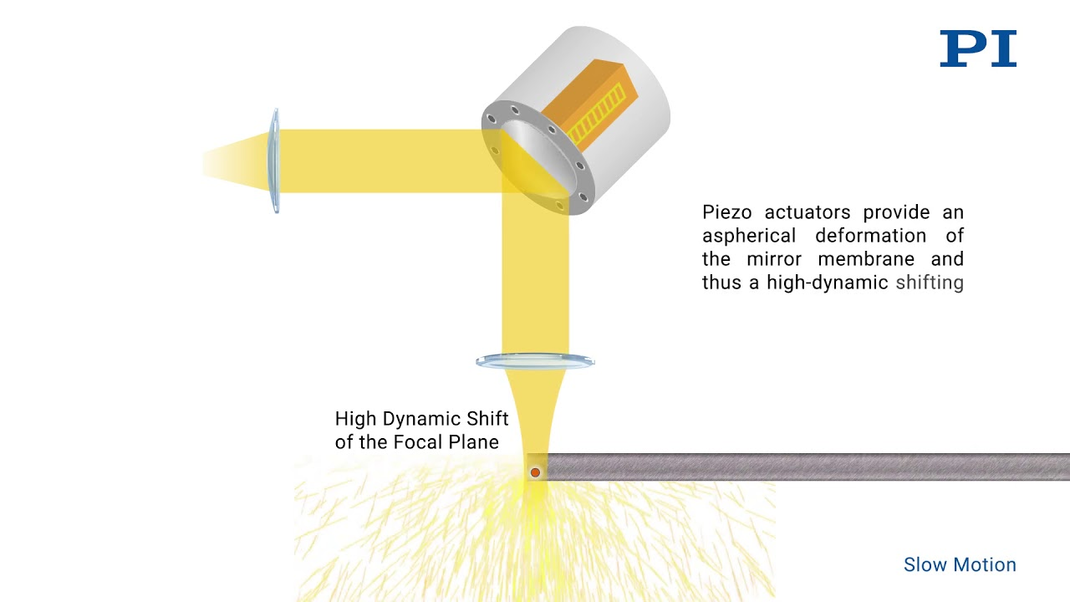

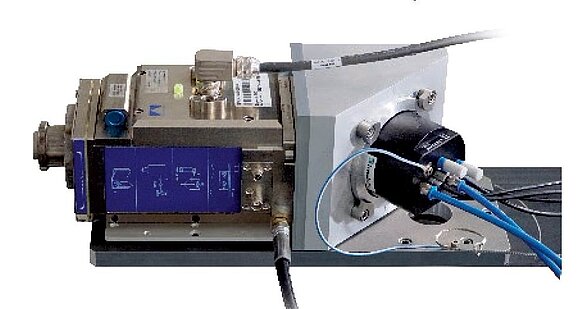

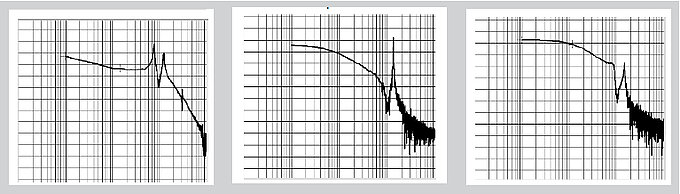

Actively shifting the beam focus on the workpiece is another method to increase the usable feed rate during laser beam cutting of thick sheet metal. During laser beam welding, it can also enable better weld seam quality and process stability. PI developed a piezo-based, high-dynamics Z axis focus shifter module in cooperation with the Fraunhofer IOF, the Fraunhofer IWS, and the industrial partners Kjellberg Finsterwalde, Heliatek and Optics Balzers. The module can be combined with conventional methods and also 2-D beam manipulation in the XY machining plane, adding highly dynamic Z-axis focus manipulation capabilities in the direction of the beam axis, increasing the machining speed while improving the quality as well.

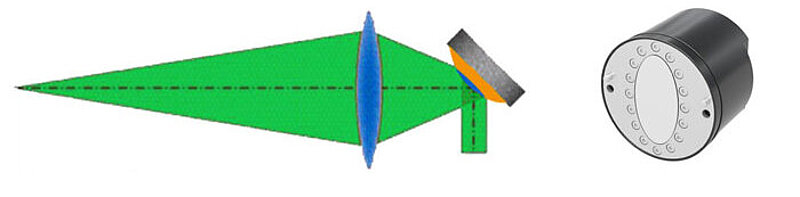

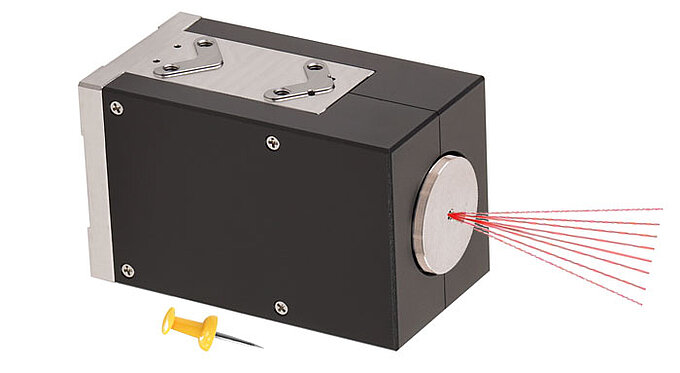

The design features an elliptical aspheric mirror membrane to avoid imaging errors and maximize the beam aperture. The dielectric coating provides high reflectivity.

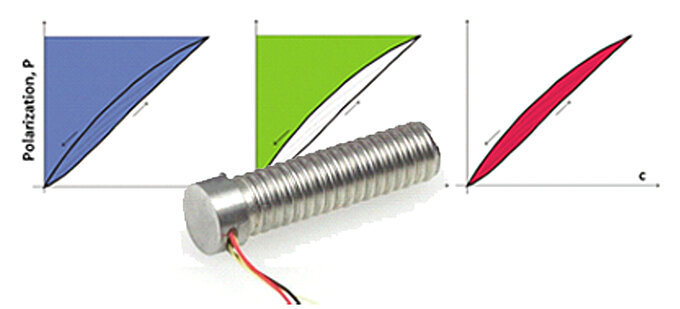

A PICA-Thru© piezo actuator element, manufactured at PI’s piezo ceramics division generates the force to deform the mirror. This type of actuator provides very high reliability and allows for optimized cooling or applications that require an aperture for optical or mechanical purposes. The actuator is driven by a high performance piezo amplifier of the E-481/E-482 series. These amplifiers make use of a patented energy recovery circuit improving the efficiency compared to conventional piezo amplifiers significantly.