In vitro diagnostics (IVD) offers many possibilities for an early diagnosis and detection of diseases. These tests are carried out with blood, saliva, or urine samples which were taken from the body of humans or animals. Fast, simple, and generally available testing methods ensure a therapeutic intervention aimed at a personalized medicine to heal, tread, and prevent diseases. Some IVD tests are designed to be used in a laboratory, whereas portable point-of-care devices can be used almost anywhere.

Not a Simple Task: Liquid Handling for IVD

The requirements of liquid handling in IVD devices are extremely demanding: Very small volumes of liquids with different characteristics need dosing or must be moved with high precision. The technology used must be able to implement shock-free dosing, fast mixing, or separation of liquids and particles as well as the generation of perfect droplets while considering the viscosity and surface tension of the media and the dosing speed. Mixing or sorting tasks are often executed contactlessly to avoid contamination of the samples.

The actuators used for nano- or picoliter liquid handling applications must work at high operating frequencies of up to several kHz while producing the kinetic energy required to generate small liquids flows or tiny droplets. Piezoelectric components and actuators are suitable for these challenging demands: The piezoelectric effect is based on the generation of charges through the application of force by a crystal and vice versa; therefore, piezo components work with an instantaneous displacement when a voltage is applied. These components mostly operate with low power consumption and are therefore predestined for operation in battery-driven devices. They exhibit durability as well as reliability, making them suitable to be employed in point-of-care applications as well as large lab automation devices.

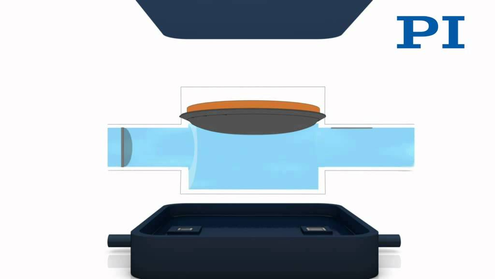

Micropumps for Portable PoC Devices

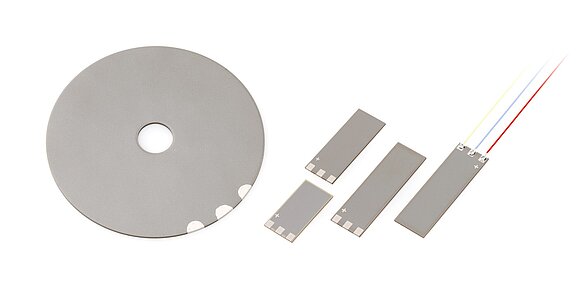

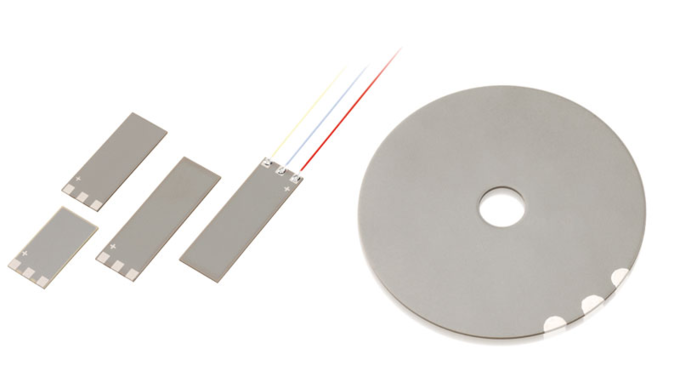

Piezoelectric microfluidic devices are used for distribution tasks whenever small volumes of liquids, in the milli- to picoliter range, must be controlled. >> Piezo components such as plates and discs are suitable products for microfluidic devices that require shock-free pumping of small liquid volumes over a certain period. To transfer their bending displacement to liquid chambers that move liquids, the piezo devices can be glued onto substrates. Miniaturized plates work as actuators in lightweight micropumps with dimensions of less than one millimeter, which can be integrated in portable point-of-care devices

Energy-Efficient Piezo Valves for Battery-Operated PoC Devices

Besides pumps, valves are often used in IVD microfluidic devices. Piezo valves are highly suitable for these applications: The piezo actuators switch the valve directly and are able to work against a closing spring or a flexible tube for volume displacement. Even with very low power, the piezo valve maintains its current position – energy is only needed when the shape of the piezo element has to be changed.

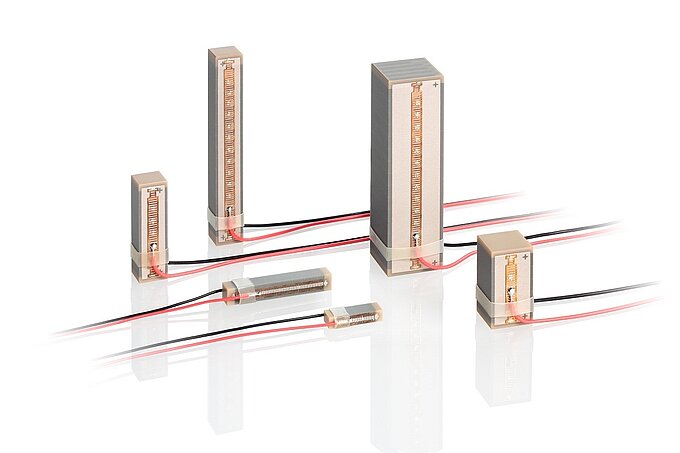

Piezoelectric valves can be designed with >> PICMA® Multilayer Bending Actuators exhibiting a displacement of up to a few millimeters depending on their design. Due to their low layer thickness and the low energy consumption, these bending piezo actuators are ideal for battery-operated point-of-care devices. The piezo actuators ensure very low flow rates that can be controlled by the driving voltage of the piezo using proportional technology.